BMW’s creative division Designworks has teamed up with The North Face to design a futuristic camper concept, which

The camper, on display at the Consumer Electronics Show, is made from outdoor product company The North Face’s innovative Futurelight fabric, which uses nanospinning technology to create what it describes as “the world’s most advanced” breathable and waterproof material.

Also known as electrospinning, the technology uses electric force to spin nano-fibres together. Using this method enables the creators to add air permeability into the membrane of the Futurelight fabric.

The process creates nano-sized holes in the material, allowing for high porosity while still maintaining full waterproofness, letting air move through the material for optimum ventilation.

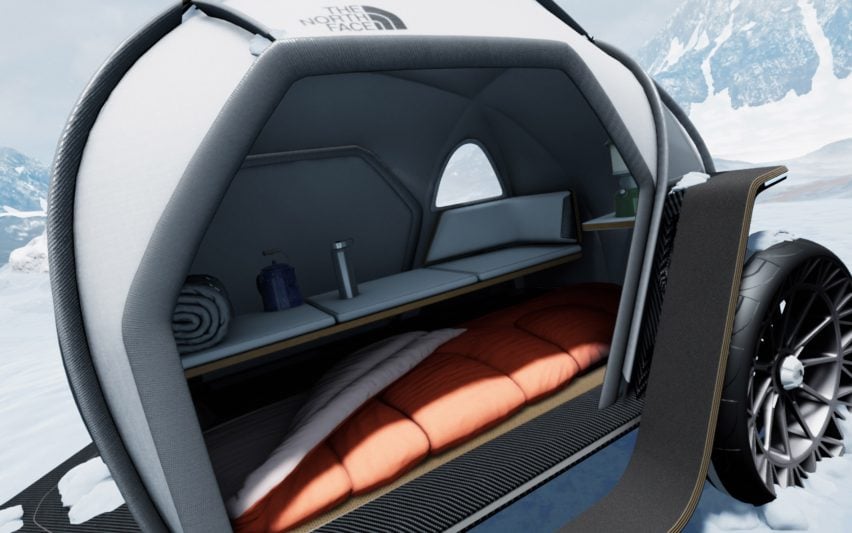

Inspired by the 2008 BMW GINA concept car, the camper features a lightweight fabric outer shell formed from the flexible Futurelight material being stretched out over a geodesic dome frame typically seen in The North Face’s tents.

This shell is mounted on a movable platform, which acts as a towable trailer, while the interior is kitted out with sleeping space for two, and shelving to allow for life on the road.

“We combined both physical and digital worlds to showcase this material, ensuring the holistic vision of the brand was clearly communicated, while giving people a real ‘hands-on’ experience,” said Designworks studio director Laura Robin.

“Thinking about extreme performance in new and unexpected ways from our experience of working across multiple industries helped us to provide consumers with a unique and never before seen insight into the very heart of the material and its key attributes,” she added.

The North Face plans to launch its Futurelight fabric this year in its Fall 2019 product line, where it will be featured across the brand’s “pinnacle performance” collections.

By Natashah Hitti